円型生爪

soft jaws

円型生爪とは?

薄物削りに多発する現象である、変形、ビビリ対策に威力を発揮する、パワーチャック用、スクロール用生爪です。

円型生爪使用の利点

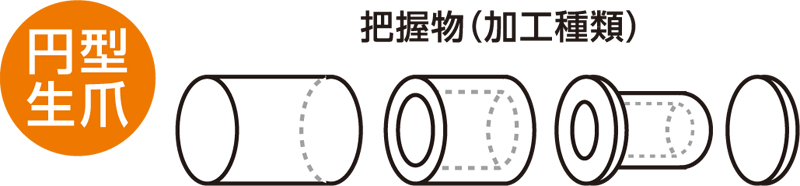

- 薄物、薄板、パイプ状の材料を変形なく把握できる。

- 異形状の把握が容易である。四角形、多角形

- 形状を抜くことで、多種多様な用途が広がる。

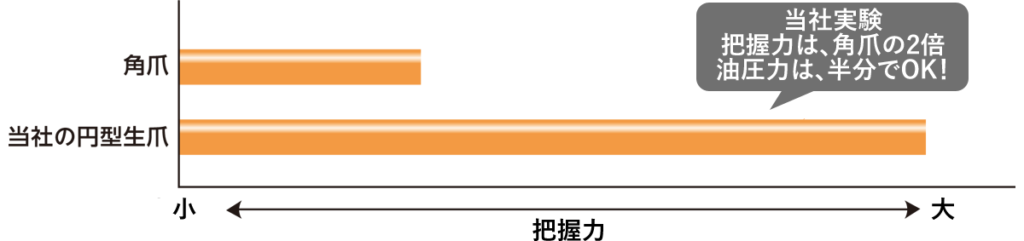

円型生爪は把握力が違います。

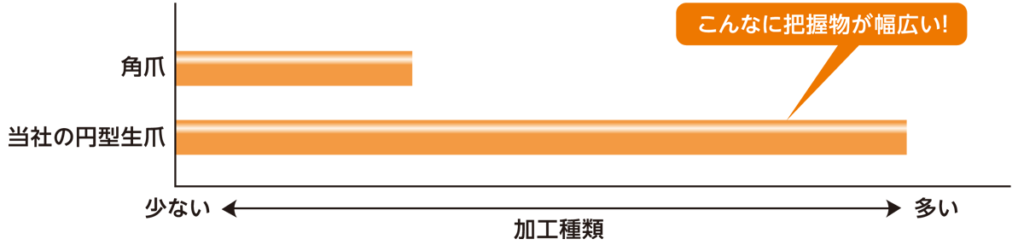

円型生爪は把握幅が違います。

- 角爪が幅3cmの棒状で、3方向(3点)から材料を固定するのに対して円型生爪は120°扇形で包み込む形状。

- 円型生爪は高速加工時のバランスにも配慮して仕上げています。

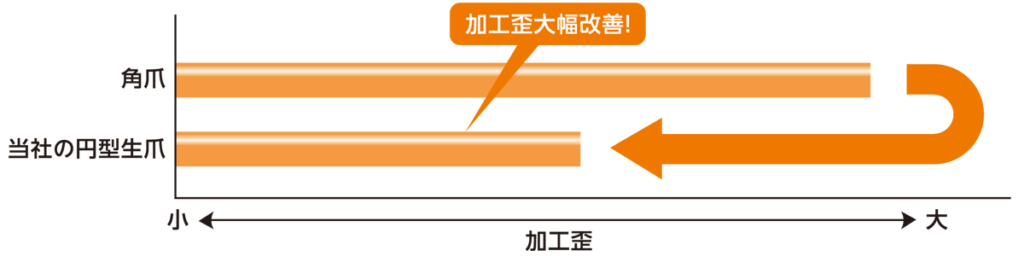

歪軽減『120°生爪』

角爪と当社円型生爪の加工歪 比較図

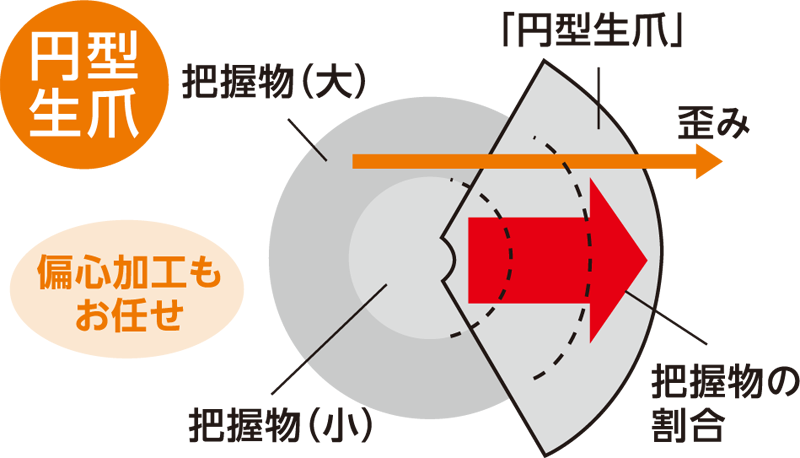

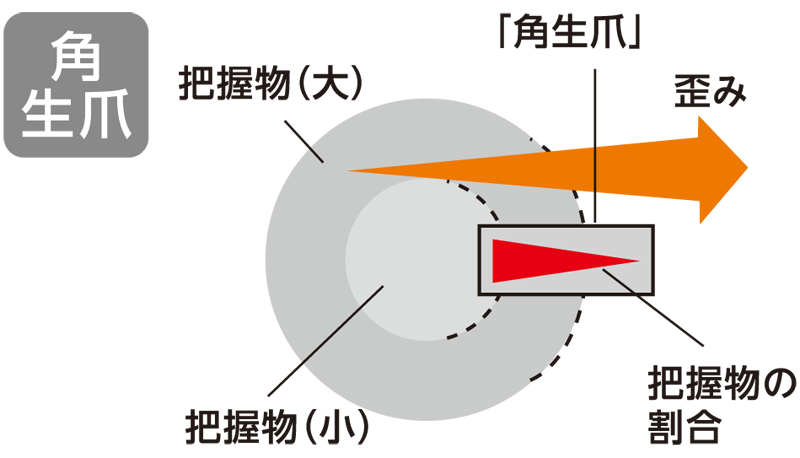

NC旋盤用生爪 歪理論を図解してみました。

円型生爪は120°の扇状のため、把握物が大きくなっても把握幅が一定の大きさを保ち、歪みの発生を抑えることができます。

角生爪の場合は把握物が大きくなると、把握幅の割合が小さくなるため、歪みが発生します。加工特性からいくと角生爪はベストじゃないですよね!

偏心加工もお任せ

円型生爪は把握物が広い!

角爪一辺倒で全ての形状の加工を行っていませんか?

実は『角爪』は中実加工にのみ最適な爪なのです。

把握物が空洞のものや薄物などの場合、角爪で締め付けるとそこに力がかかりすぎる場合があり、時には歪みやビビリの原因になっている場合があります。その点、扇爪は掴む面積が広くなる分、力のかかり方が角爪よりも均一になり、歪み軽減やビビリ防止に役立つと言えます。

円型生爪は把握物を選びません!

爪で数値を比較してみました

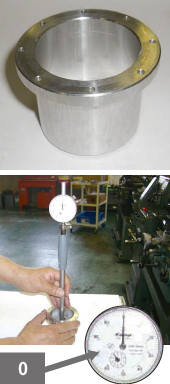

円型生爪の良さを目で知ってください!

計測前、製品が歪んでないことを確認し『円型生爪』と『角爪』のアルミ円筒品加工の度合いを測ってみました。

チャッキング前

歪み:0

角生爪でチャッキング

歪み:2/100

円型生爪でチャッキング

歪み:0 数値変動なし!