High-Tech Processing Solutions

Orders from Prototypes

We are commited to provide our clients with systems suitable for prototype manufacturing processes and assemblies, guaranteeing stable and accurate products.

In addition, we support the assembly of high precision parts, by means of carefully performed processes in a temperature controlled room.

Processing Equipment

・Machining Center・Numeric Control Lathe・Multifunction Machine・General Purpose Machine・Polishing・

We manufacture parts of various geometries and sizes, due to our evergrowing assortment of machining centers and processing tools.

Since we take deep care about our customers and their time, we are self sufficient throughout the whole manufacturing process, from the material acquisiton to the delivery of the product. This ensures strict control and outstanding quality.

At TEKNIA, we execute grinding and metal cutting processes to produce mechanical parts of various geometries. Contact us for prototype inquiries.

-

5-Axis Machining

We manufacture products with complex curved surfaces by means of our 5-axis machining equipment, HyperMill and CAD/CAM.

5 Surface Processing Machine

This process allows the manufacture of long shafts, plates and cans of H1600 × D2000 × L4000. Equipped with CNC indexing, cut big cams of D600 × L3500 are also performed. Machining accuracy is in the range of 0.01mm within 400mm range for flatness, parallelism and pitch.

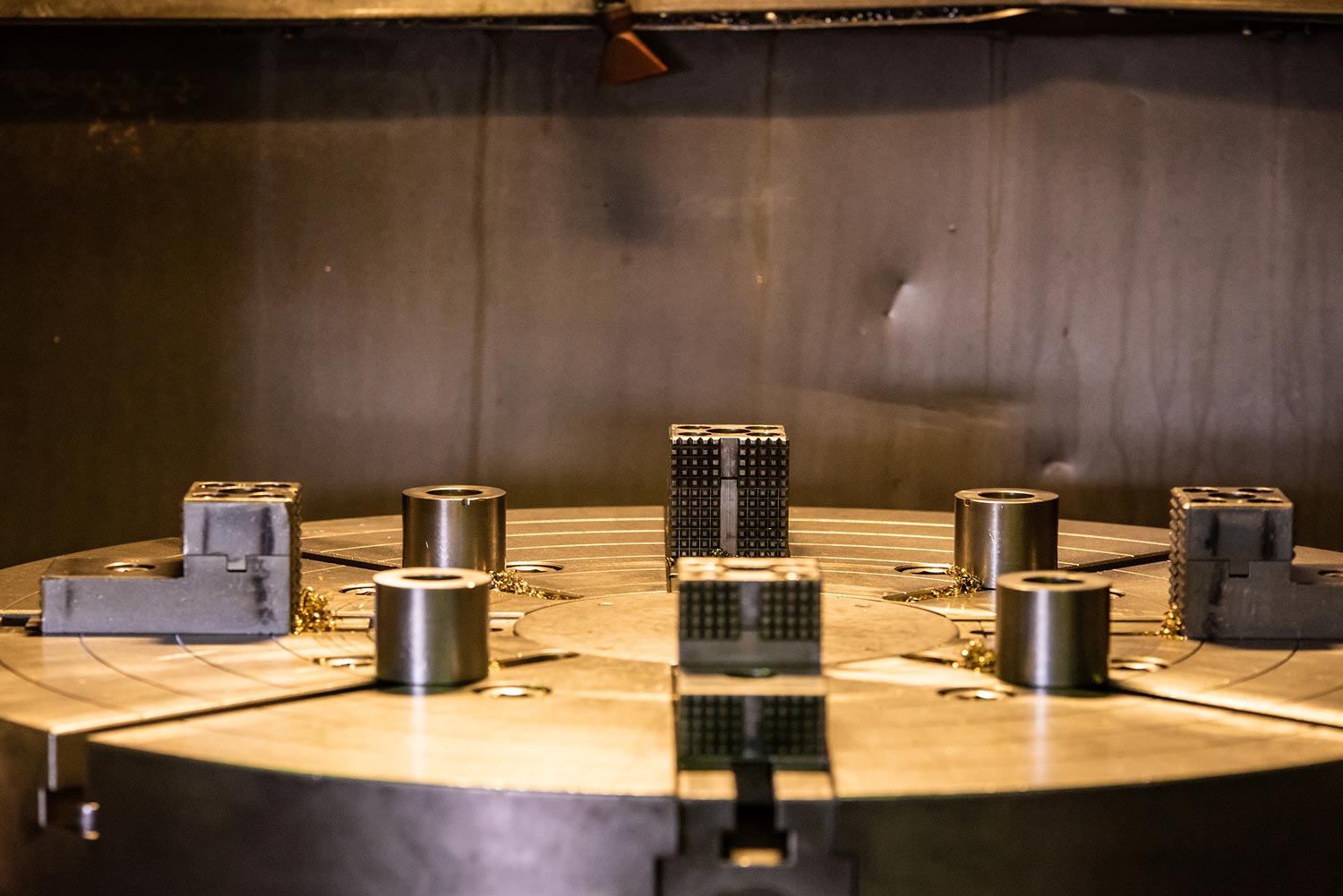

Turning

We are prepared to receive orders for pieces from medium to big size, with diameters varying from 400 mm up to 1000 mm. Considering customers may need a small production quantities, we gladly accept small batch orders.

-

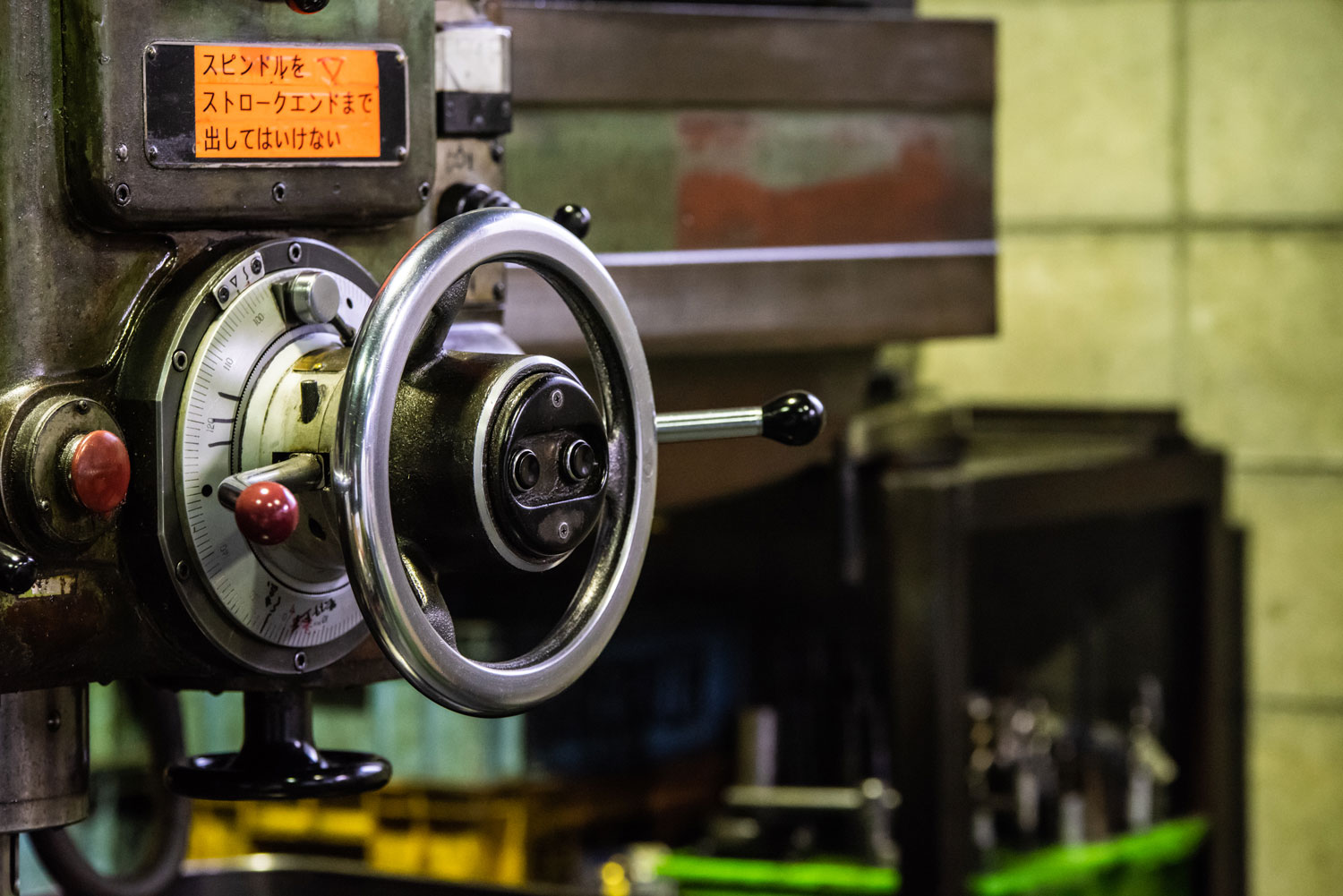

General Purpose Machining

High precision machining is guaranteed by our highly skilled technicians. Our efficient jig producing technology and know-how accumulated over many years, making us suited to carefully produce your orders, including small batches.

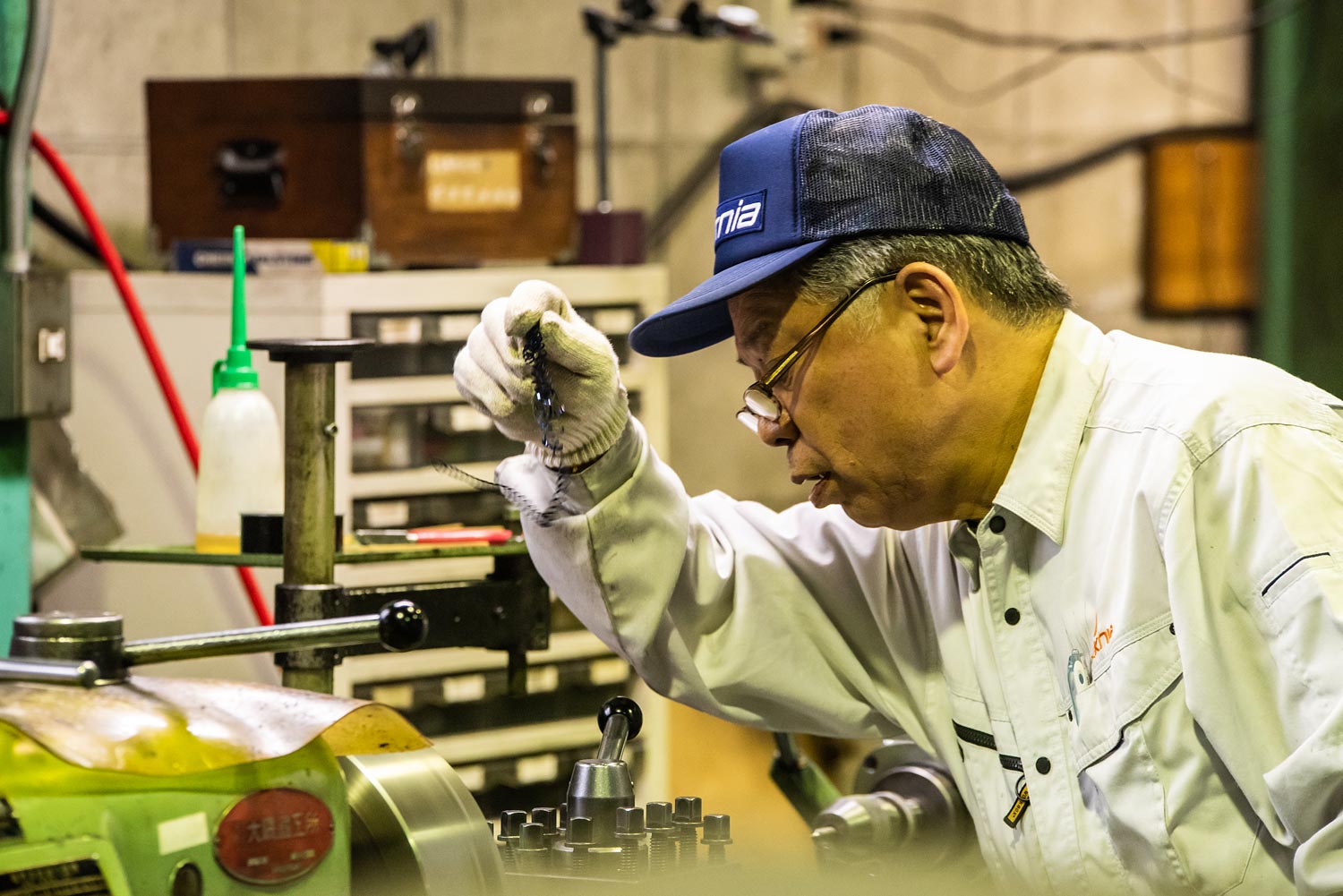

Polishing

Polishing is the last and most step. It determines the quality of every product. Our variety of polishing machines can operate with roughnesses in the order of microns. We are also capable of doing polishing to machine parts that have been induced to heat treatments, such as quenching.

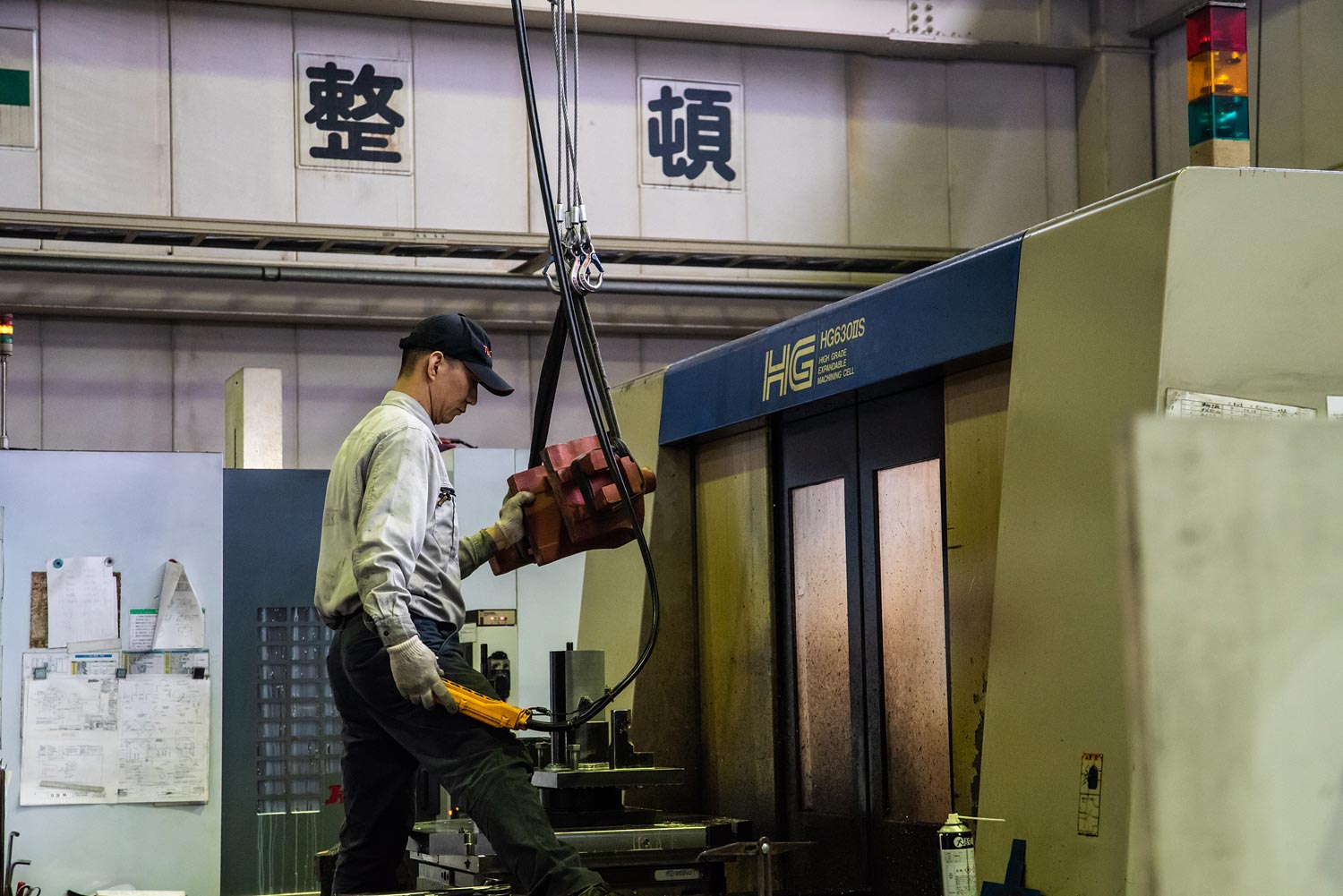

Cutting Tools

The manufacturing industry does not only involve the production of mechanical parts, but also the setup of manufacturing systems. Besides, with the introduction of multifunctional machines, multi-step machining (including oblique machining) can be completed with one chucking processes. Therefore, TEKNIA is capable to perform multi-side machining without scratches and within short delivery times. Thus, we manufacture every kind of KM - MT - BT - NT cutting tool holders.

-

BT30 Machining Center Spindle Assembly

Our spindle assemblies from 5000 up to 15000 rpm have achieved productions up to 3000 parts. In addition, manufacture specifications such as interlocking, bearings fitting, and assembly details are in the order of microns. Taking this into account, we have accumulated know-how throughout many years and have confirmed ourselves, that it may lead to a substantial cost reduction.

Thinking on our customers benefit, we are prepared to offer short delivery and production times with reasonable prices. We do so by applying a synchronous production method and quick shipping response system (24h Factory Operation).

With the introduction of the FMS - Flexible manufacturing system method and system machine that has a jig pallet of 80 sides, it is possible to deal immediately with various types of orders from our customers, such as: small batch production, various geometries, shapes, variable quantities and design variations. This allows us to ship a wide variety of items within short delivery time.

OEM Tooling

Being aware that our products will be used in many important applications, we use a solid quality control system. Consequently, we keep control of every operation within the manufacturing process, from raw material (upstream control) to heat treatment (downstream control). We will provide then BT, HSK and GM cutting tools, and your own rotation tool.