Manufacturing technical support

Based in our experiences and achivements, we will provide to our costumers an optimum production planning, design and manufacturing process according with our costumers requirements. We also provide JIG design for the costumer’s internal manufacturing process.

Manufacturing Process Design

An optimum and efficient production planning and manufacturing process design, are indispensable for the advanced QCD (quality, cost, delivery) in our products.

We provide consulting and support for optimal and efficient manufacturing process design including production plans, work contents, task issues, etc., in response to costumer product requirements.

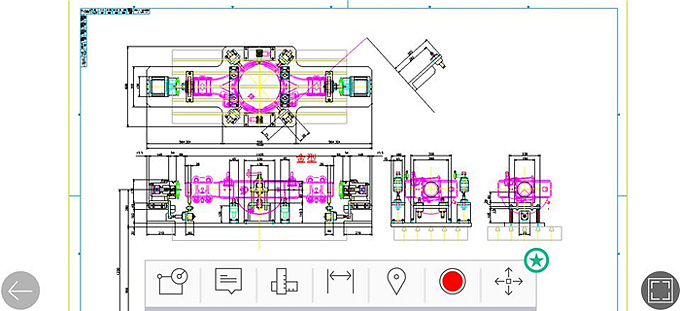

Jig Design

Based on manufacturing process design, we undertake the design and manufacture of the jigs in order to streamline the actual manufacturing process. The performance of the jig used is important to achieve the best QCD and create a product that meets the requirements.

TEKNIA boasts a high product quality, based in years of experience on design, manufacturing and using high technology. As a result of this experience, we also produce general-purpose jigs suitable for a wide range of applications, and custom jigs tailored to our customers needs.

At TEKNIA, manipulation scratches and dent marks are unacceptable. Often high accuracy of microns is required, therefore, a highly advanced technology is required in the manufacturing process. By using TEKNIA’s high precision fixture, we accomplish advanced QCD requirements.

Equipment・ Equipment Design Support

In order to respond to the requested QCD, it’s indispensable a constant improvement in facilities, equipment, etc. We provide equipment proposal and design support.