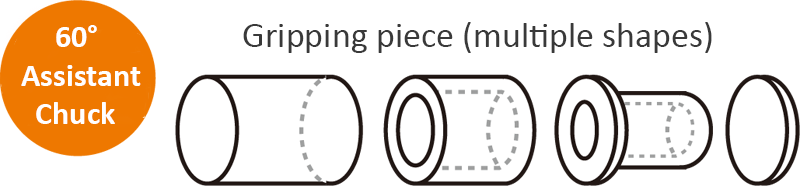

60° Assistant Chuck

What is a 60° Assistant Chuck?

When fixing material strongly with an angled chuck, the material is deformed, hence Mr. Takahashi developed a 60° Assistant Chuck. Since the force is uniformly applied to the workpiece (in comparison with the angle chuck), it is possible to suppress deformation.

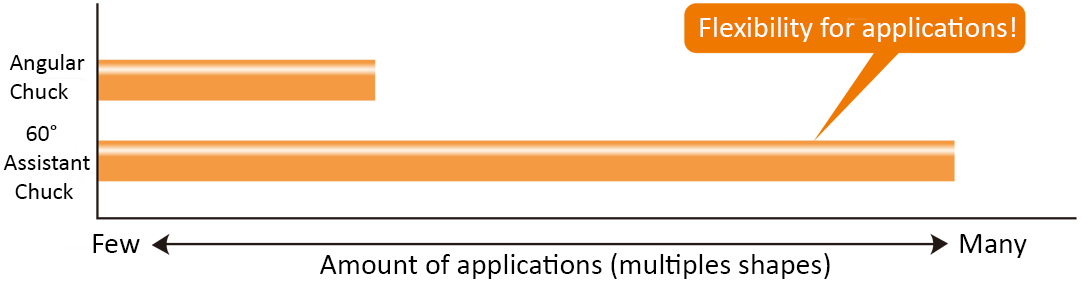

Advantages of using a 60° Assistant Chuck

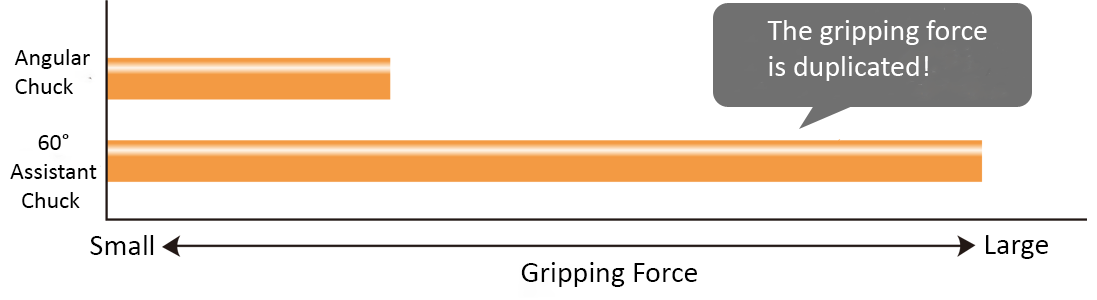

- The gripping force is higher in comparison to the angle chucks.

- Be relieved about workpiece distortion, because with the assistant chucks the force is applied on a surface, rather than a point.

- The gripping width increases in comparison to angle chucks.

60° Assistant Chuck's difference in gripping force

60° Assistant Chuck's difference in gripping width

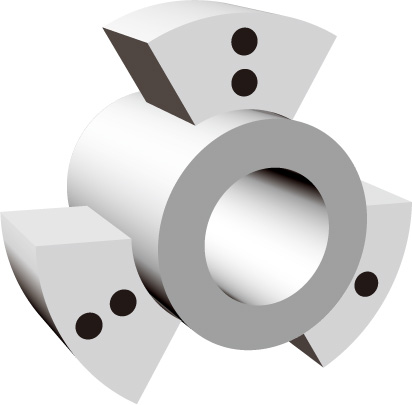

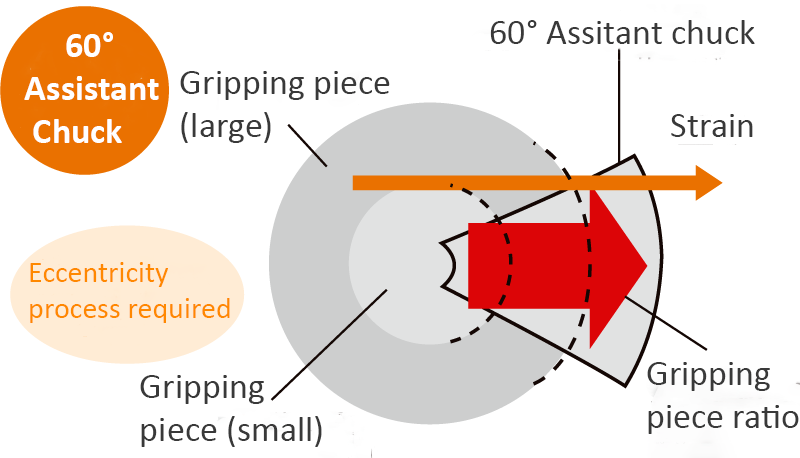

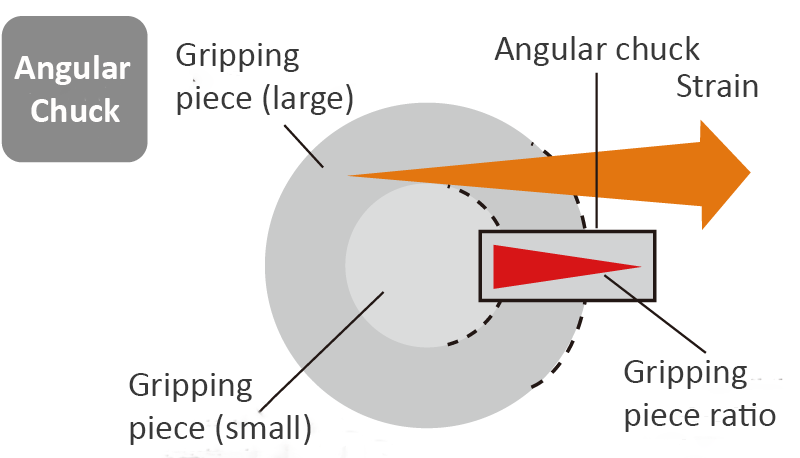

- The angle chucks are bars of 3 cm width, that hold the material from 3 different points. On the other side, the 60° Assistant Chuck has a fan shape with grabbing angles of 60°.

- The 60° Assistant Chuck is also designed well balanced and compatible with high speed machining processes.

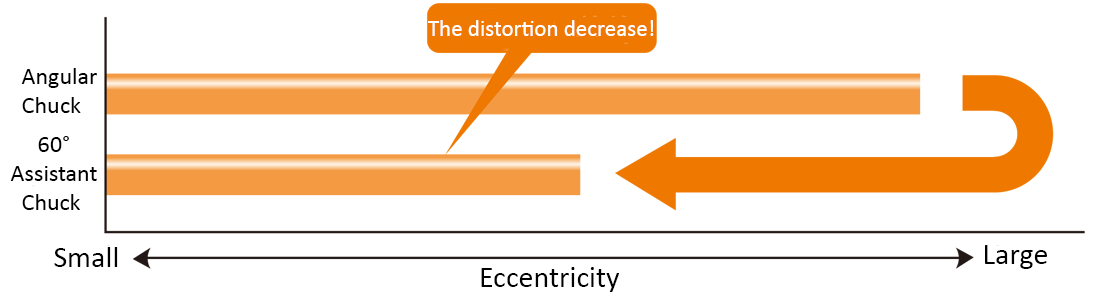

Distortion reduction with 60° Assistant Chucks

Comparison of machining generated distortion between Angle chucks and 60° Assistant Chucks

Explanation and Theory of distortion in NC Lathe Process.

The 60° Assistant Chucks is fan-shaped, so even if the grasped object gets bigger, the gripping width is kept at a certain size. Thus the occurrence of distortion can be suppressed.

In the case of an angle chuck, distortion occurs because the proportion of gripping width decreases as the workpiece grows. Hence it is not the best for narrow specifications.

Requirements for Eccentric Processes

60° Assistant Chucks' width is bigger.

Have you ever done all the machining process with a single chuck?

Actually, these 60° Assistant Chucks are the best for solid processing.

In the case of holding hollow or thin objects, there may be situations where excessive force is applied on a point of contact, even when tightening with a torque wrench. Sometimes it may cause undesirable effects such as distortion and chatter. In that matter, it can be said that our chucks are more effective for strain reduction and chattering, as the area of gripping becomes wider while the applied force becomes more uniform through the angular chuck.

You should not be limited by the chucks!