Processing Equipment

Our Equipment

In order to respond to the diversifying needs of our customers, we are actively introducing state-of-the-art technology in our production facilities and preparing production systems suitable to carry out special orders. For the sake of delivering various kinds of high quality products, such as aircraft and machine tool parts, we are eagerly pursuing the Total Merit policy. By doing so, the accumulated know-how knowledge will lead to quality improvements and cost reductions, while focusing on nurturing and training advanced technical capabilities.

Nagoya Factory Equipment - Overview

-

OKUMA Vertical

OKUMA Vertical

Machining Center MCV-AⅡ -

OKUMA Vertical

OKUMA Vertical

Machining Center MILLAC-852V -

MAZAK Vertical

MAZAK Vertical

Machining Center NEXUS 510C -

OKK Vertical

OKK Vertical

Machining Center VM-4Ⅲ -

OKK Vertical

OKK Vertical

Machining Center VM-7Ⅲ -

TOSHIBA Horizontal

TOSHIBA Horizontal

Machining Center BTD-200QF -

TAIYO Compound

TAIYO Compound

Polishing Machine VerticalMate55 -

Mitutoyo CNC

Mitutoyo CNC

3D Coordinate Measuring Machine Crysta-ApexC121210

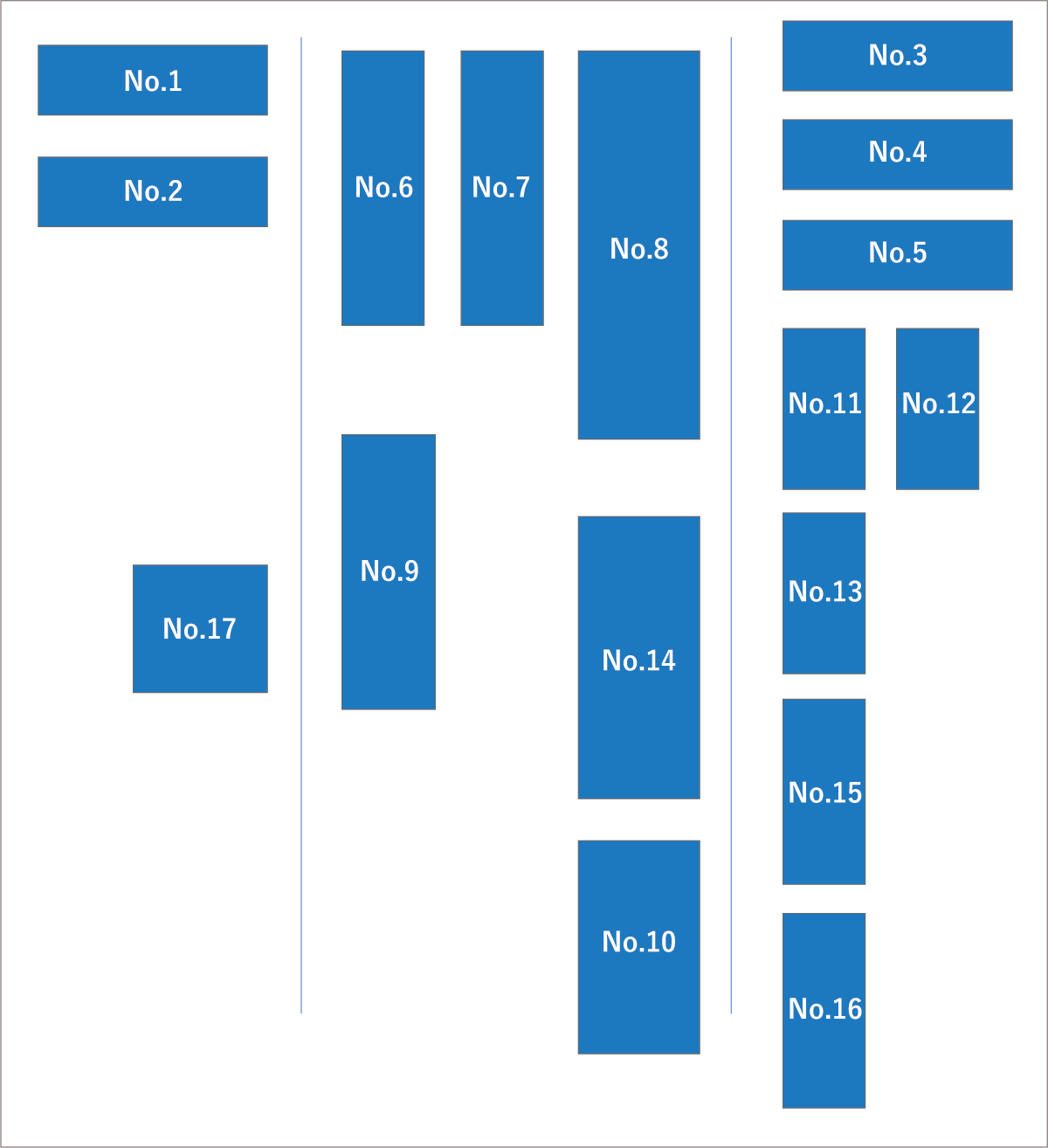

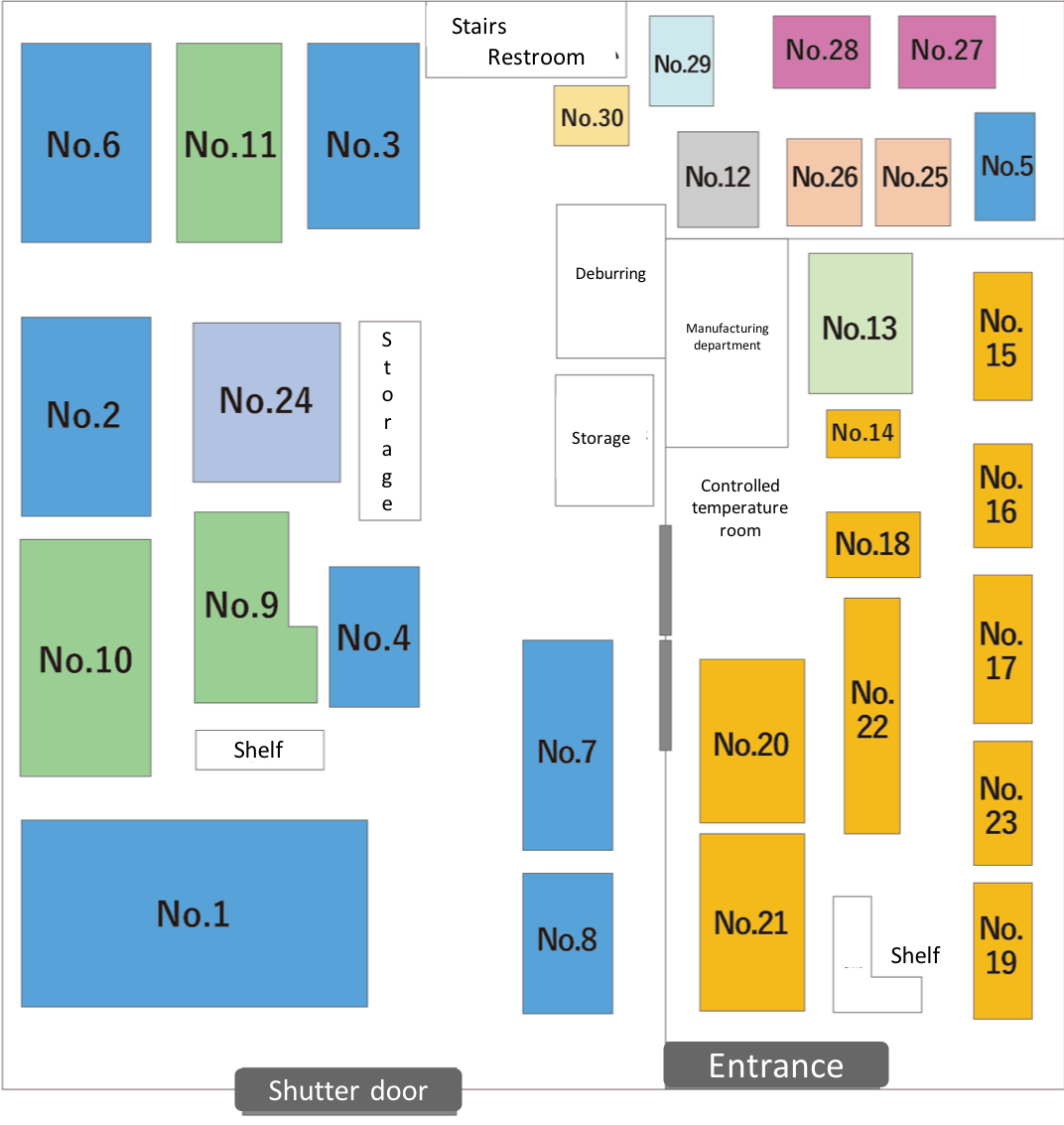

Nagoya Factory Equipment List

| Machine Type | No. | Machine Details | Manufacturer | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model Number | Table Size | Rotation Speed | |||||||||

| Machining Center | 1 | Vertical | MCV-AⅡ | 4000×1800 | 50 | OKUMA | |||||

| 2 | MC-60VA | 1250×650 | With C-axis | 50 | OKUMA | ||||||

| 3 | AJV-25/405 | 1000×500 | With C-axis | 40 | MAZAK | ||||||

| 4 | NEXUS 510C | 1120×550 | MAZAK | ||||||||

| 5 | VM-4 | 800×500 | OKK | ||||||||

| 6 | VM-7Ⅲ | 1400×800 | With C-axis | 50 | OKK | ||||||

| 7 | MILLAC44V | 600×400 | 40 | OKUMA | |||||||

| 8 | DuraVertical 5060 | 900×600 | 40 | DMG MORI | |||||||

| 9 | Horizontal | BTD-200QF | □1000 | 1PC | 50 | TOSHIBA | |||||

| 10 | A77 | 40 | MAKINO | ||||||||

| 11 | A55 | 40 | MAKINO | ||||||||

| Wire Cut | 12 | HS-50A | 410×260 | BROTHER | |||||||

| Vertical Grinding | 13 | Vertical Mate 55 | φ550 | TAIYO | |||||||

| Polishing Machine | 14 | Side Grinding | GS-BH3-R | KURODA | |||||||

| 15 | GHL-B512P | 1250×560 | NC polishing | HITACHI工 | |||||||

| 16 | ε2-360 | 600×300 | NC polishing | Nagase Integrex | |||||||

| 17 | Internal laboratory | Y1G-20-MRD | YAMADAKOKI | ||||||||

| 18 | Y1G-20-MSA | 200×200 | YAMADAKOKI | ||||||||

| 19 | IGM-1T | OKAMOTO | |||||||||

| 20 | IGS-4NT | NC polishing | TAIYO | ||||||||

| 21 | External laboratory | 2OKVA | NC polishing | TSUGAMI | |||||||

| 22 | GUP-100 | 310×1000 | TOYODA MACHINE | ||||||||

| 23 | G32 GOS32×50 | TOYODA MACHINE | |||||||||

| Honing | 24 | T-3214 | TOYO | ||||||||

| Milling Machine | 25 | Vertical | NH-3VⅡ | 480×680 | OKK | ||||||

| 26 | SHI2VOKA | ||||||||||

| Universal Lathe | 27 | LPT-35C | φ185 | WASINO DMG MORI | |||||||

| 28 | LS2232 | φ380 | OKUMA | ||||||||

| Radial Drilling Machine | 29 | YR5-1300 | YOSHIDA | ||||||||

| Drill Machine | 30 | KRDG-420 | KIRA | ||||||||

Nagoya Factory Layout

Aisai Factory Equipment(Overview)

-

MAZAK NC Lathe

MAZAK NC Lathe

NC Lathe POWER MASTER -

OKUMA Turning mill

OKUMA Turning mill

NC Lathe V100R -

OKUMA 1Saddle

OKUMA 1Saddle

CNC Lathe LB3000 EXII -

MAZAK MULTI

MAZAK MULTI

Composite Lathe INTEGREX200J -

OM Turning mill

OM Turning mill

Composite Lathe Omega50 -

KITAMURA Horizontal

KITAMURA Horizontal

Machining center HX-630I -

MORI SEIKI Horizontal

MORI SEIKI Horizontal

Machining center NH6300 DCGⅡ -

KIWA Horizontal

KIWA Horizontal

Machining center KNH-426 -

MAKINO Horizontal

MAKINO Horizontal

Machining center J3 FORMULA -

OKUMA Vertical

OKUMA Vertical

Machining center MCV-A5C -

OKUMA Vertical

OKUMA Vertical

Machining center MB-56VA -

MAKINO 5-axis

MAKINO 5-axis

Machining center V55-5XA -

DMG 5-axis

DMG 5-axis

Machining center DMU50 -

OPEN MIND CAD/CAM Hyper MILL

OPEN MIND CAD/CAM Hyper MILL -

Dassault Systemes CAD/CAM CATIA V5

Dassault Systemes CAD/CAM CATIA V5

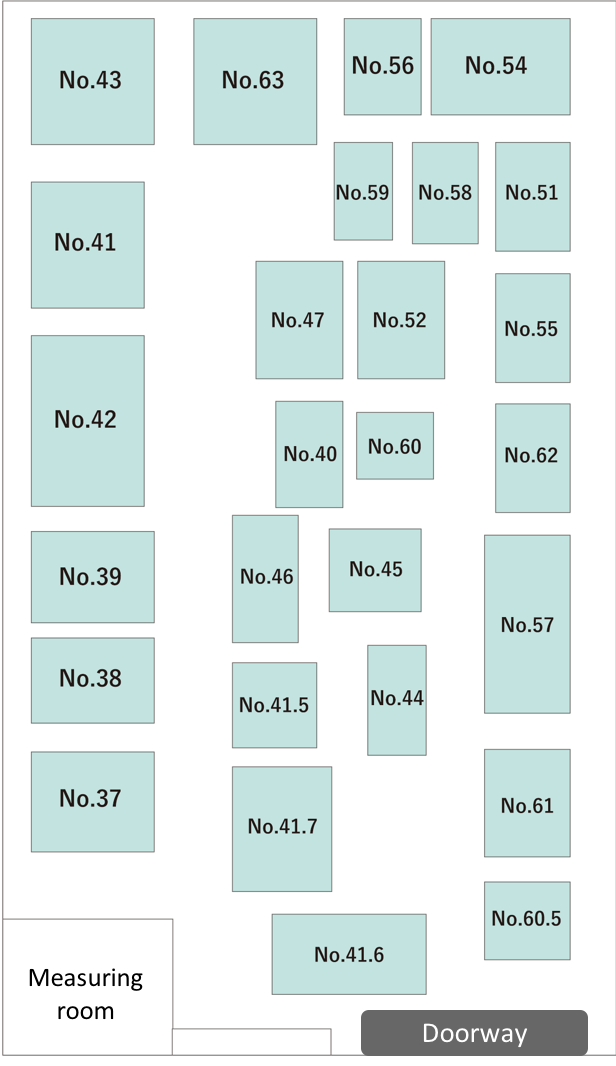

Aisai Factory Equipment List

| Machine Type | No. | Type | Machine Details | Manufacturer | ||||

|---|---|---|---|---|---|---|---|---|

| Model Number | Table Size | Note | ||||||

| NC Lathe | 37 | NC Lathe | SQT-15M | 8inch | MILL+ | MAZAK | ||

| 38 | SQT-15MS | 8inch | MILL+ | MAZAK | ||||

| 39 | QT-28 | 10inch | MAZAK | |||||

| 40 | QT-35 | 15inch | MAZAK | |||||

| 41 | POWER MASTER | φ800 | MAZAK | |||||

| 41.5 | X-150 | TAKAMAZ | ||||||

| 41.6 | XL-150 | TAKAMAZ | ||||||

| 41.7 | LB3000EXⅡ | OKUMA | ||||||

| 42 | Turning mill | V100R | φ1000 | Turning | OKUMA | |||

| Mill Turn Center | 43 | MULTI | Super Hisel | 10inch | Ber Feeder | HITACHI SEIKI | ||

| 44 | INTEGREX200Y | 8inch | MAZAK | |||||

| 45 | INTEGREX200J | 8inch | MAZAK | |||||

| 46 | INTEGREX30 | 12inch | MAZAK | |||||

| 47 | Turning mill | Omega50 | φ1000 | Turning | OM | |||

| Machining Center | 51 | Horizontal |

HG630 | □630 | BT50 2PC | HITACHI SEIKI | ||

| 52 | HX-630I | □630 | BT50 2PC | KITAMURA | ||||

| 54 | KNH-426 | □400 | BT40 6PC | KIWA | ||||

| 55 | KNH-426 | □400 | BT40 6PC | KIWA | ||||

| 56 | J3 FORMULA | □400 | BT40 2PC | MAKINO | ||||

| 57 | NH6300 DCG Ⅱ | □630 | MORI SEIKI | |||||

| 58 | Vertical | AJV-18 | 560×410 | BT40 2PC | MAZAK | |||

| 59 | α-T14iD | 300×500 | BT30 +1axis | FANUC | ||||

| 60 | MB-56VA | 1000×560 | HSK-A63 | OKUMA | ||||

| 60.5 | MILLAC 852V | 2200×850 | BT40 | OKUMA | ||||

| 61 | 5-Axis | V55-5XA | □400 | HSK-A63 | MAKINO | |||

| 62 | DMU50 | φ300 | BT40 | DMG | ||||

| 63 | Gate model | MCR-A5C | 5000×2000 | OKUMA | ||||

Aisai Factory Layout

Gujo Factory Equipment

Gujo Factory Equipment List

| Machine Type | No. | Type | Machine Details | Manufacturer | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model Number | Table Size | Note | ||||||||

| NC Lathe | 1 | NC Lathe | XL-150 | 8inch | 2 | TAKAMAZ | ||||

| 2 | Full Automatic | 5inch | 2SET 6LINE | SB | ||||||

| 3 | 〃 | 〃 | 2 | 〃 | ||||||

| 4 | 〃 | 〃 | 2 | 〃 | ||||||

| 5 | 〃 | 〃 | 2 | 〃 | ||||||

| Machining Center | 6 | Horizontal | MH633 | □630 | 10PC | DMG MORI | ||||

| 7 | MH633 | □630 | 10PC | 〃 | ||||||

| 8 | SH8000 | φ1300 | 25PC | 〃 | ||||||

| 9 | SH8000 | φ1300 | 25PC | 〃 | ||||||

| 10 | NMH10000DCG | 1500X1300 | 5axis | 〃 | ||||||

| 11 | Vertical | TMV-1500A | 1600X762 | TONGTAI | ||||||

| 12 | TMV-1500A | 1600X762 | TONGTAI | |||||||

| 13 | TMV-1500A | 1600X762 | TONGTAI | |||||||

| 14 | TMM-16-20-N | φ1600 | Turning | OM | ||||||

| 15 | 5axis | RB-200F | 4000X2000 | HSK-A100 | SNK | |||||

| 16 | Gate model | RB-4NM | 600X530 | BT40 | SNK | |||||

| 3D Measuring Instrument | 17 | PRISMO 7 | TONGTAI | |||||||

Gujo Factory Layout