TEKNIA GROUP : cutting work, parts machining, soft jaws, Human resource development, Temporary staffing, TEKNIA College

HOME > Parts machining | Assistant industry in 2009

Assistant industry in 2009

Setup by general purpose small |

As an assistant industry in 2009, we have undertaken the task of the following.

The studying themeIn recent years, 6-4 titanium is commonly used for aircraft parts. We study the 6-4 titanium cutting method, its cutting tools and surrounding tools using a small general purpose machining center. Also, in order to accommodate the aircraft parts, we have installed the 3D CAD/ CAM (CATIA5 ), and examine the process flow from modeling, processing to the measurement. Background (aircraft industry)Recently, fuel-efficient passenger aircrafts are much in demand because of the fuel costs rising. For that reason, carbon is commonly used for air frame structure. As a result of this, titanium alloy which is compatible with carbon is adopted, and the number of parts is increasing. However, the process of the difficult-to-cut material titanium alloy takes much time and costs. Therefore, the study of the 6-4 titanium cutting method makes our technique improved, and we consider that orders in aircraft industry will be competitive. It is a studying to propose the best cutting tool and processing condition by 9 companies of tool makers. |

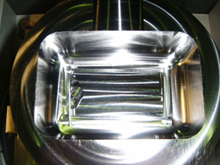

Pocket processing |

Chase processing |

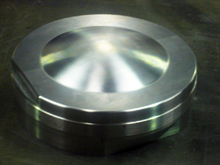

3D processing |

||

|

|

|

||

Virtual aircraft parts processing from CATIA data |

||||

|

|

|||

For any inquiries about process, please contact Kawachi. (planning sales department manager)

TEKNIA Co., Ltd.

Head office, Nagoya factory

3-459 Ematsu, Nakagawa-ku,

Nagoya city, Aichi, Japan

TEL.+81-52-303-3347

FAX.+81-52-303-3354

Aisai factory

5-1 Rokujutsubo, Nishiho-cho,

Aisai city, Aichi, Japan

TEL.+81-567-28-9051

FAX.+81-567-28-9050

E-mail info@teknia.co.jp