TEKNIA GROUP : cutting work, parts machining, soft jaws, Human resource development, Temporary staffing, TEKNIA College

HOME > Soft jaws | The order soft jaws

The order soft jaws

We provide the best soft jaws and hard jaws in compliance with the customers' request.

We manufacture jaws which is suited to each chuck maker.We handle various kinds of requests, for example, the hard jaws which meets the size and shape of workpiece.

What are the merits?

- Enable to process workpiece which is difficult to process.

- Enable to show processing know-how to customers.

- Enable significant time crunch of centering working hours

Examples of products

|

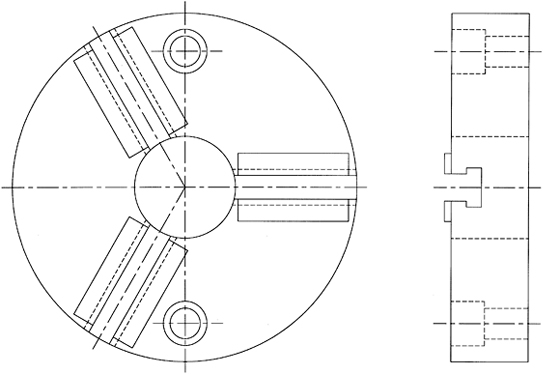

Chuck jaws "Kaku-san" Cost down. *When workpiece is thin or hollow, we recommend "soft round jaws" or "60-degree soft jaws Suke-san". |

|

|

Hard chuck jaws "Kaku-san hard jaws" "Kaku-san hard jaws" is hard jaws which is hard and not easy deformation because soft jaws are quenched. |

The requirements for orders

Analysis of cutting environment

It is essential to analyze cutting environment when we manufacture order-made soft jaws.

- What you process

- Kind of machines

- Kind of chucks

- Rotation rates, feed and the amount of cutting

Three elements

Manufacturing of order-made soft jaws need three elements, "base material", "cutting" and "finishing jigs".It becomes the best soft jaws only after completing these three elements.

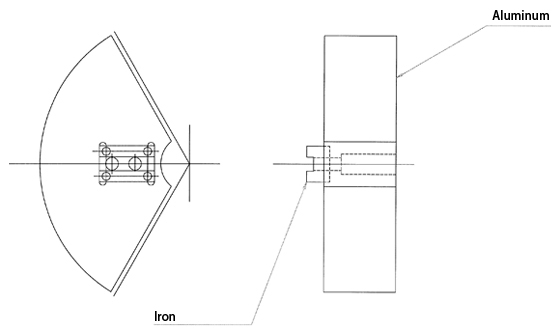

| Base material | First of all, manufacturing of order-made soft jaws start choosing the best base material which is suited to processing parts. We have our know-how to choose the best base material from abundant records in the past, considering varieties of terms such as the material, degree of hardness and shapes. |

|---|---|

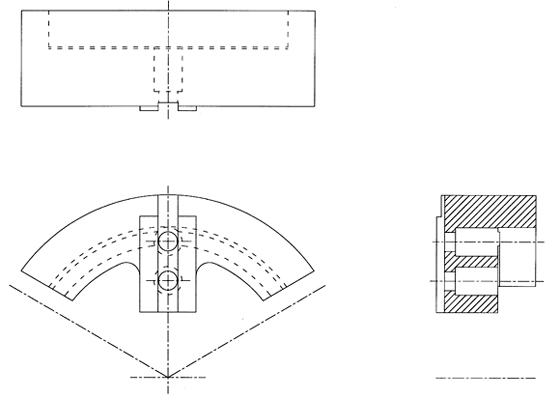

| Cutting | If you make a mistake in centering, the shape of quarter sector become unbalance and it has influence on vibration of cutting, shaking and finishing surface roughness. This shape processing skill is also Teknia's strong point. |

| Finishing jigs | Tools of finishing jig are stockpiled to offer low prices. |

The order type referential production drawing

Besides the following, we examine responded to customer's requests.

Please feel free to inquire.

Aluminum soft round jaws

It prevents abrasion of...

Soft round jaws of special shape

It eases weights when you use high jaws.

Shaping jigs of soft round jaws (work shaping base)

Manufacturing as to the form of chucking

TEKNIA Co., Ltd.

Head office, Nagoya factory

3-459 Ematsu, Nakagawa-ku,

Nagoya city, Aichi, Japan

TEL.+81-52-303-3347

FAX.+81-52-303-3354

Aisai factory

5-1 Rokujutsubo, Nishiho-cho,

Aisai city, Aichi, Japan

TEL.+81-567-28-9051

FAX.+81-567-28-9050

E-mail info@teknia.co.jp