CHUCKS AND SOFT JAWS

What is a Chuck?

When cutting thin materials, there is a recurent phenomen known as vibrations. Those vibrations can produce chatter marks and physical transformations in the material. Therefore one must take countermeasures to assure the absence of this non desired effects. With the use of power chucks and scroll chucks, this inconvenience can be avoided.

Why use a chuck?

- You can grasp thin materials, thin plates and pipe-like materials without generating any deformation.

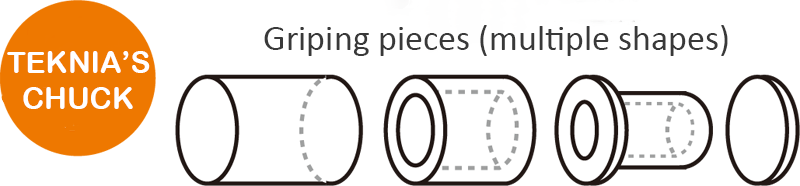

- It is easy to grasp different shapes such as rectangles or polygons.

- Considering that different soft-jaws can be used with a single chuck, the range of applications can be boosted.

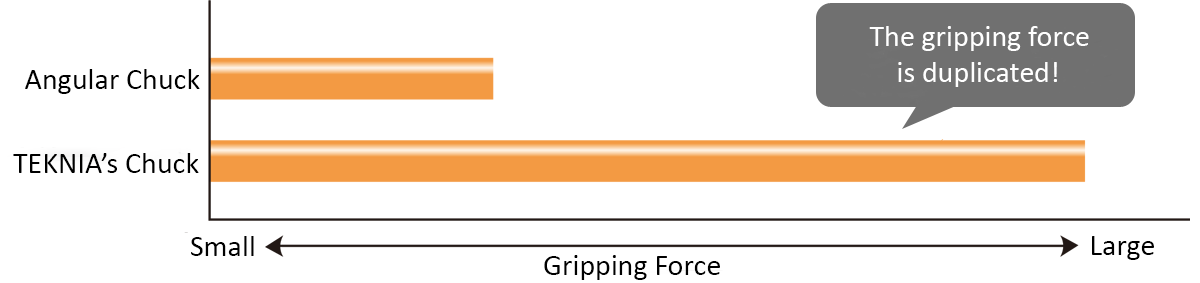

Gripping Power

Grip width

Chuck

Soft-jaws

- Soft-jaws have 3cm of width, they are fixed to the chucks and are spaced by 120°, allowing to grap the material from 3 direcctions.

- Chucks are designed considering requirements for high-speed machining.

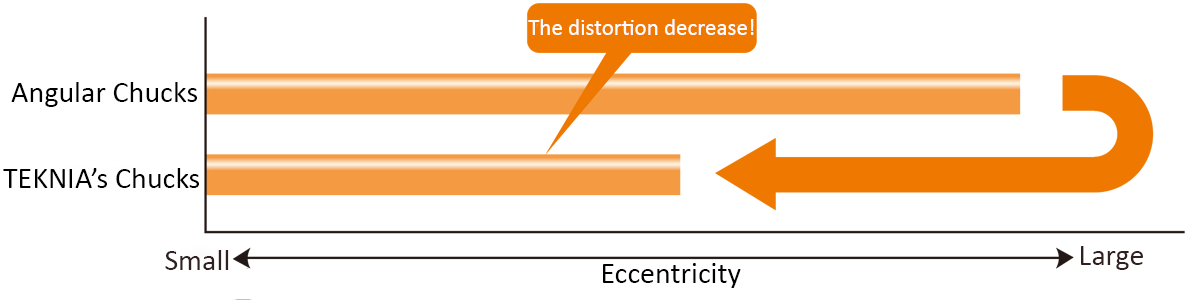

Distortion reduction (120° Chucks)

Machining Distortion Comparison

Distortion due to NC Lathe

As a result of the 120° fan like shape of the chuck, the grasping width keeps teh fixed size and the distortion can be suppressed, even if the grasped object becomes larger.

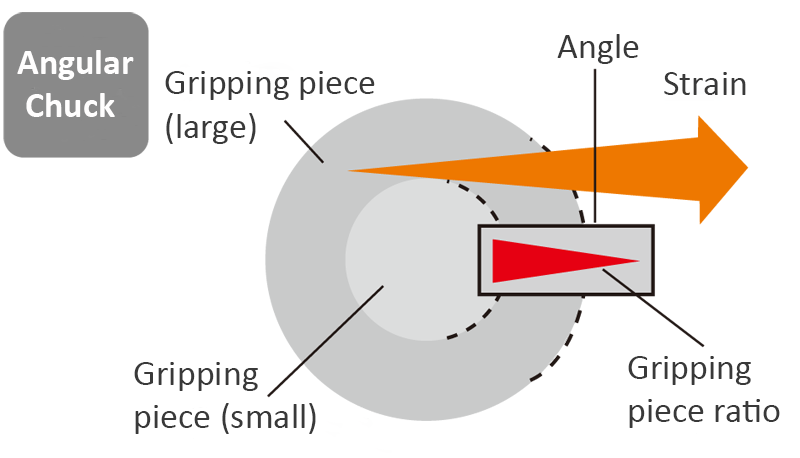

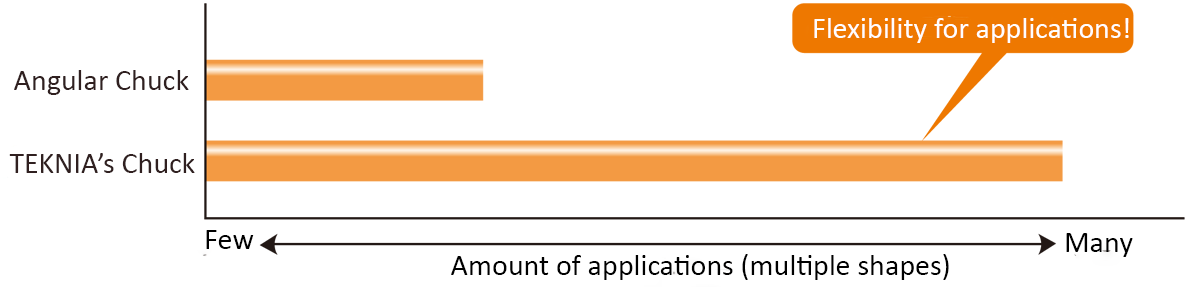

In case of the angled chucks, distortion occurs because the ratio of grasping width decreases as the size of the object grows. Therefore the angled claws are not able to process complex geometries, large pieces or designs with special specifications.

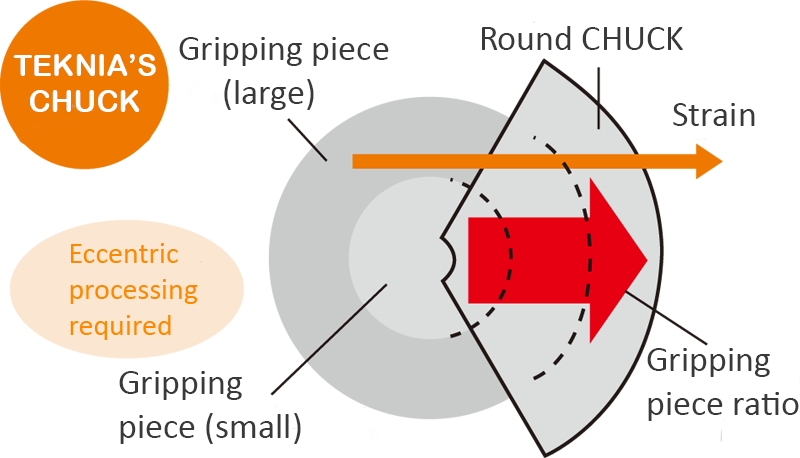

Eccentric Processing

Chucks have a wide grasping range!

Actually, these chucks are the best for solid processing.

In the case of holding hollow or thin objects, there may be situations where excessive force is applied on a point of contact, even when tightening with a torque wrench. Sometimes it may cause undesirable effects such as distortion and chatter. In that matter, our chucks are more effective for strain reduction and chattering, as the area of grasping becomes wider while the applied force becomes more uniform than if the angular chuck is used.

You should not be limited by the chucks!

Comparison of Chucks Accuracy

Please note the amazing performance of our chucks!

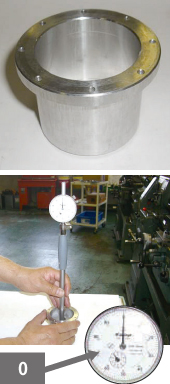

We measured eccentricity in an aluminum cylinder after grasping, to confirm that it was not distorted. We show examples of grasping with our round chucks and another squared ones.

Initial Eccentricity Measurement

Distortion:0

Angular Chucks

Distortion:2/100

Round Chucks

Distortion:0 (Without numerical variation)